|

|

|

The Forge Forging

gives steel great strength, in this photograph taken in 1954 we see

our Vulcanists using a 10 ton (20000lb) steam hammer to work the red hot metal that will become a

locomotive connecting rod one of the most stressed parts of a

locomotive.

|

The Forge If

you thought that the hammer to the left was big then have a look at this

one which was the largest in the foundry at 50 ton (100000lb). This one

is again at work forging a connecting rod, the larger hammer was

required to work the side faces of the rod which had a larger surface

area requiring more greater force to work. |

|

Click

here for Video

|

|

|

|

|

|

Non Ferrous

Foundry

A lot of the

smaller bits and pieces required to build the Vulcans finished products were made in-house from Non-Ferrous metals (copper alloys) such as

Brass, Bronze & Gun Metal. Such items would include steam fittings,

nameplates, makers plates, whistles, bearings, handles and other bright

work. Amazingly we have dated this image to 1953 by reading the headline of

the newspaper in the wooden bench seen at the bottom right of the photo!

|

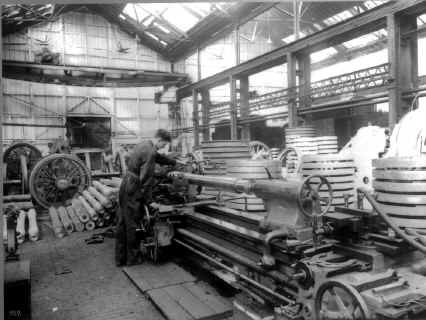

The Wheel Shop

Here we can see axles being turned on a Craven

centre lathe ready

for assembly. Cast wheels and their steel tyres lying stacked all around the man working the lathe.

|

|

|

|

|

The Erecting Shop

This is the part of the foundry where all

the ingredients that made up each locomotive were assembled or erected.

Boilers mounted in frames would be dropped onto their axles and wheels

and all the other parts attached. In the photo you can see many such

parts strewn over the floor in the foreground.

|

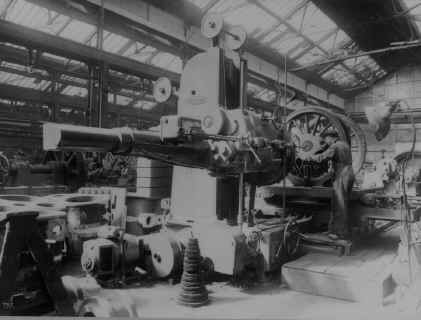

Machining Axle Assemblies

This photograph shows an axle assembly

undergoing a final machining operation on a Richards No. 5 horizontal

borer. The machine

is obscuring the tooling but the chap seems to be aligning it on the

centre of the axle, any ideas?

|

|

|

|

|

Sheet Metal Work

Ever wondered how the curvy bits were made

like the dome on top of the boiler that covered all the insulation and the

boiler itself. Well here we see two artisans working sheet metal by hand

with the aid of heat and a few hand tools. Even when most of the

locomotive was made with the aid of machinery some bits were still more

cost effectively made by hand.

|

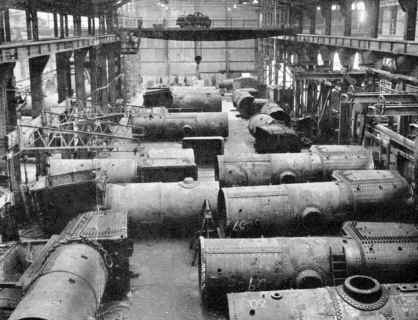

Boiler Shop

This photograph is a good view of the boiler

shop a distinct change from the more organised machine shops. Boilers

being the largest and most awkward locomotive components would be

constructed in a large open area with a high capacity overhead crane

available. As the boilers were constructed they would be rolled from one

side to the other or upended to enable all the hot rivetting to be

completed.

|

|

|

|

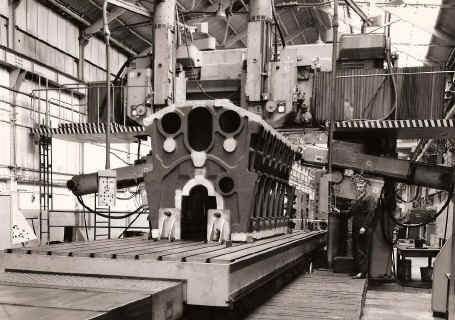

Holroyd Three Headed Slotting Machine

Built by the foundry in 1912, rough flame cut

frames would be finish machined in one go to eliminate the risk of stress

cracking from the flame cutting. The machine was completely rebuilt in

1946 and had a bed length of 90' (over 27m). This photo shows it in its

rebuilt state machining a stack of 16 frames with the other heads hidden

behind the first.

|

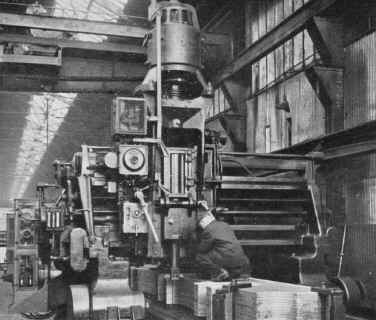

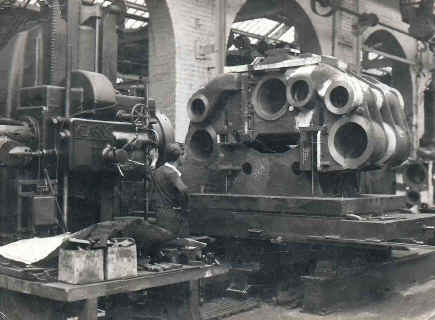

KEARNS Horizontal Borer

Ken Johnson using a Kearns No. 5 Borer to

bore out steam cylinders in the late 1940's or early 1950's.

|

|

|

|

Noble & Lund Plano-Miller

Les Jarrett machining a crankcase for a

A.T

12 cylinder 'V' form Diesel in Bay 3 or 4?.

|

Waldrich Siegen Plano-Miller

Les Jarrett again with

the Waldrich Siegen installed in Bay 4 (approx

1980) it replaced the old Noble & Lund Plano-miller

|

|

|

|

Camshaft Timing Roy Whittaker has sent in this photo taken in 1958

that shows Roy with a student from Jordan. Roy is assembling an

English Electric 8SRK camshaft for Argentina Railways. At this time in

1958 only the 4, 6, 8 cyl engines were assembled at Vulcan (you can

see examples in the photo) the 8, 12, 16 V engines were still being made

and tested at English Electric Preston works and delivered to Vulcan Works for fitting

into the locomotives.

|

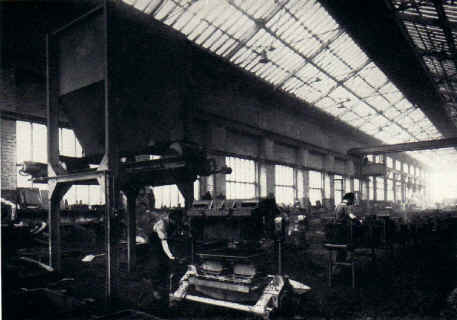

Jackman Turnover Machine in the Iron Foundry

Jackman Turnover Machine installed in the

iron foundry in the early 1950's.

|

|

|

|

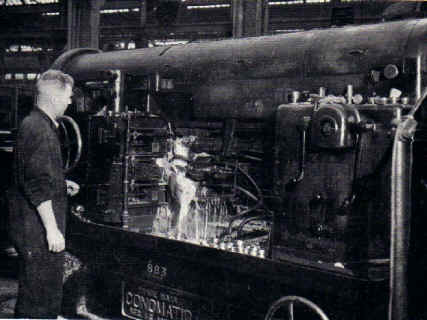

Conomatic 6-Spindle Automatic Lathe

6-Spindle Conomatic Lathe for the continuous

production of flexible firebox stays, one of 2 machines specifically

dedicated to their production after WW2.

|

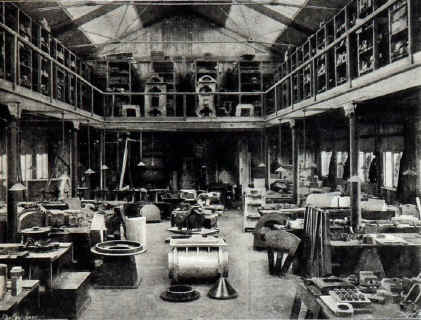

Pattern Shop 1902 Patterns

(made of wood) were used in the production of castings in the ferrous and

non-ferrous shops and were used to produce imprints of the required items

in the two halves of the sand filled casting boxes.

(If you can describe this better in one sentence then let me know)

|